CERTIFICATIONS

Onyx Solar is committed to delivering high-quality products only, which meet international standards, codes, and safety guidelines. Both the production process and materials have been verified by independent certifying associations.

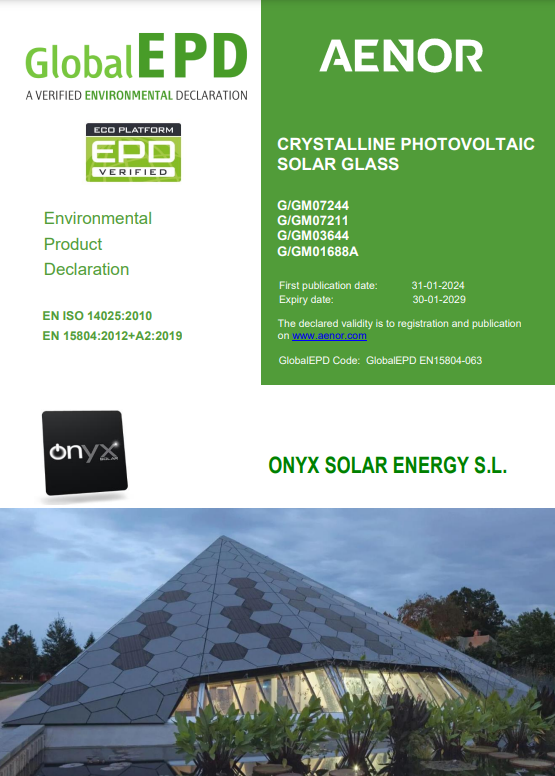

Certified Environmental Product Declaration (EPD)

The Environmental Product Declaration (EPD) is a certified document that provides our clients with reliable, verified, and transparent information regarding the environmental impact throughout the life cycle of a product. This information is based on a Life Cycle Analysis (LCA) study conducted in accordance with the Product Category Rules (PCR) developed by the Eco-labeling Program. In our specific case, the study has been carried out under the Product Category Rule for Construction Products UNE EN 15804:2012+A2. These EPDs can be downloaded by clients directly from AENOR's website.

AENOR has bilateral agreements of mutual recognition with key European Program Administrators, including EPD International AB (EIAB) in Sweden, Institut Bauen und Umwelt e.V. (IBU) in Germany, and ICMQ in Italy, which administers the EPD Italy program. This collaboration further enhances the international validity and credibility of our Environmental Product Declarations.

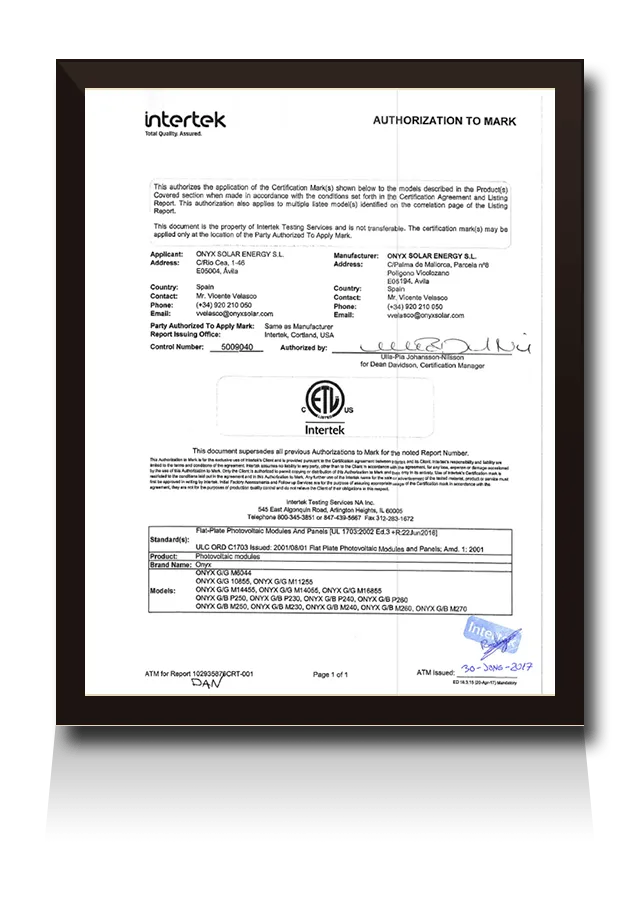

UL certification

UL is one of several companies approved by the U.S. Occupational Safety and Health Administration (OSHA) to perform safety testing. More than 50 of our products have obtained their corresponding certifications, thereby making Onyx Solar the leader in safety for photovoltaic glass in the U.S.

Onyx Solar´s crystalline and amorphous silicon glass panes were investigated by UL succesfully in accordance with the standards for safety UL-1703 & ULC/ORD-C1703 "Standards for Flat-Plate Photovoltaic Modules and Panels". This represented a milestone in the solar industry since no company had been able to certify extra-large and semi-transparent PV glass panes to this standard before.

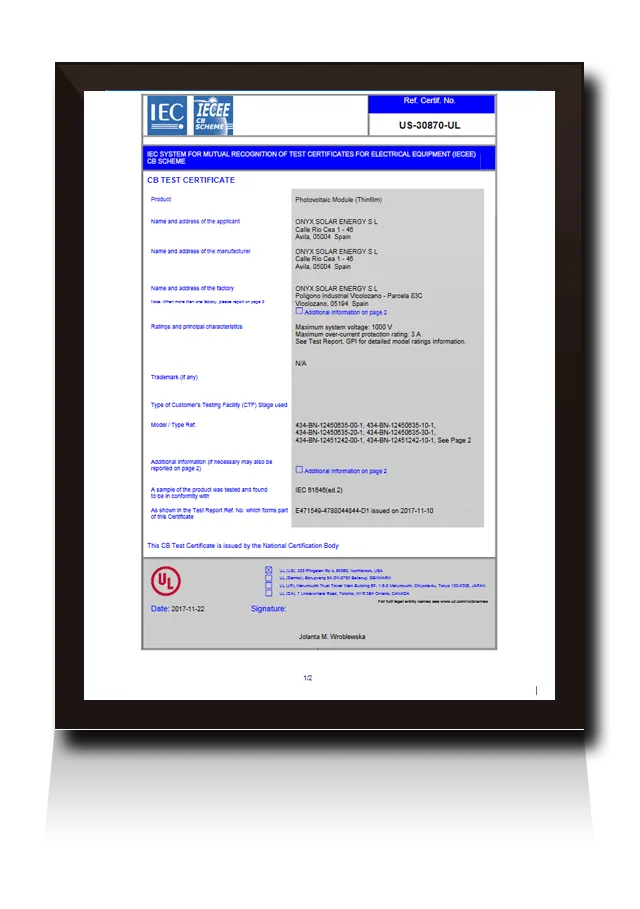

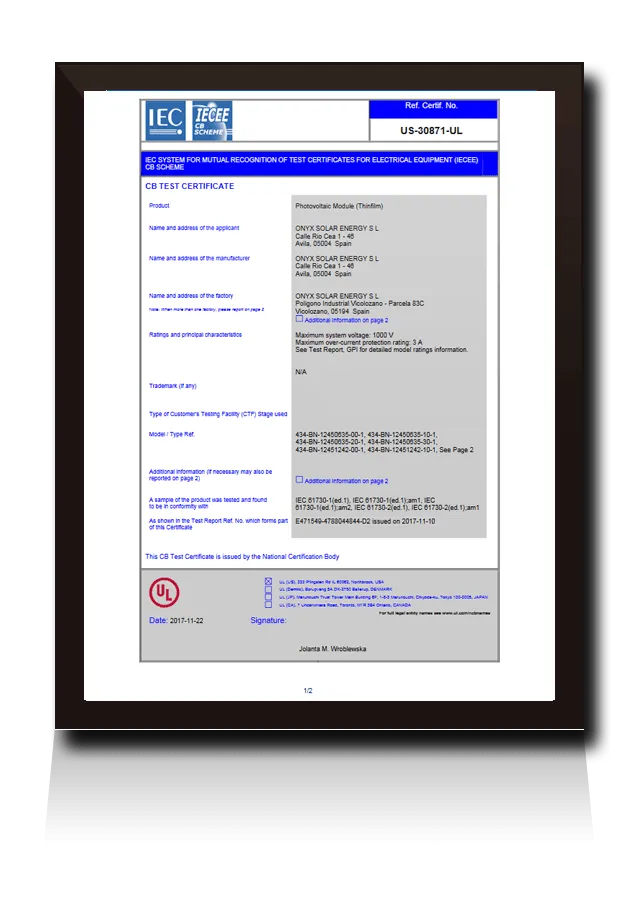

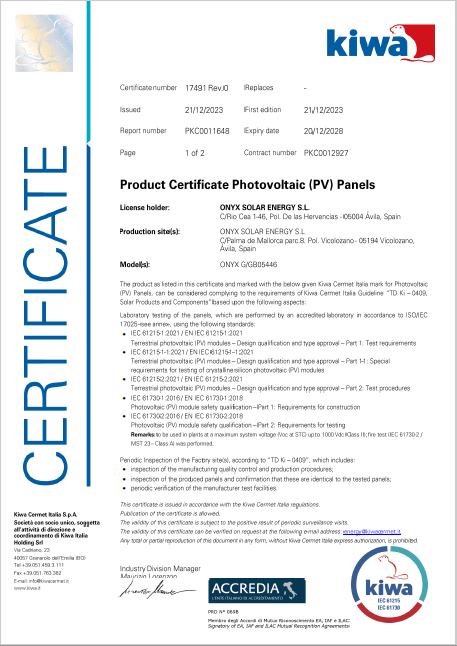

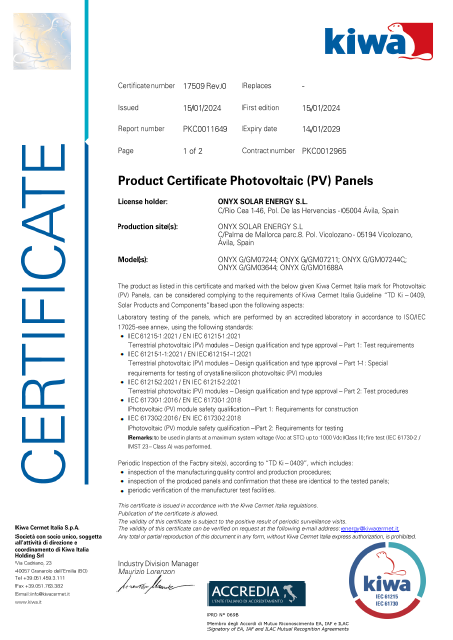

IEC Certification

The International Electrotechnical Commission (IEC) is an international organization that prepares and publishes International Standards for all electrical, electronic and related technologies. In the field of photovoltaics, it regulates the manufacture of products and ensures compliance with quality and electrical safety standards.

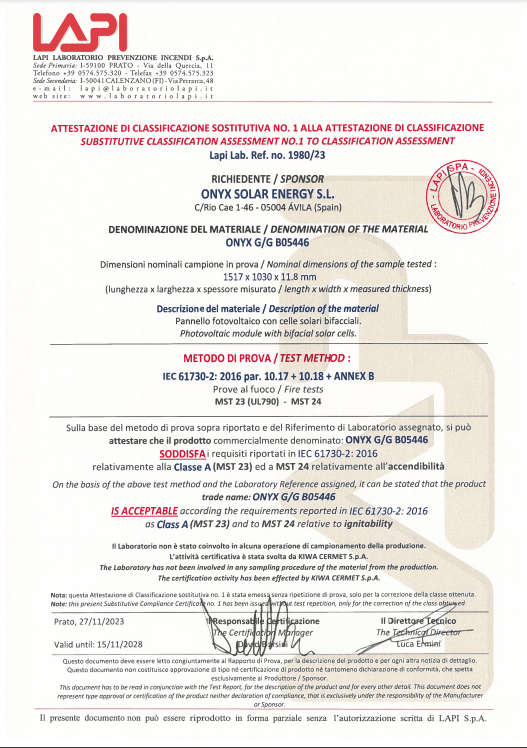

All our photovoltaic products comply with IEC61215: 2021 (Terrestrial photovoltaic (PV) modules - Design qualification and type approval) and IEC 61730:2016 (Photovoltaic (PV) module safety qualification) among many others focused on laminated safety glass that apply to BIPV.

Our products, made of amorphous and crystalline silicon glass (including our Hidden PV glass -coloured-, walkable PV floor tiles, bifacial PV glass modules and more) have passed the most stringent and strictest safety and quality tests. This allows Onyx Solar to continue to offer the highest quality products and to remain a leader in BIPV market.

These tests include inspections of our manufacturing quality control and production procedures and verification of our test facilities among other requirements.

No other manufacturer of photovoltaic glass has as many products tested with optimal results.

TÜV NORD Certification

TÜV NORD laboratories have certified both Onyx Solar’s factory and crystalline glass panes in accordance with the following IEC standards:

“Crystalline Silicon Terrestrial Photovoltaic (PV) Modules - Design Qualification and Type Approval”, and IEC61730 2011:1&2 standards

“Photovoltaic (PV) module safety qualification - Part 1: Requirements for construction & Part 2: Requirements for testing”.

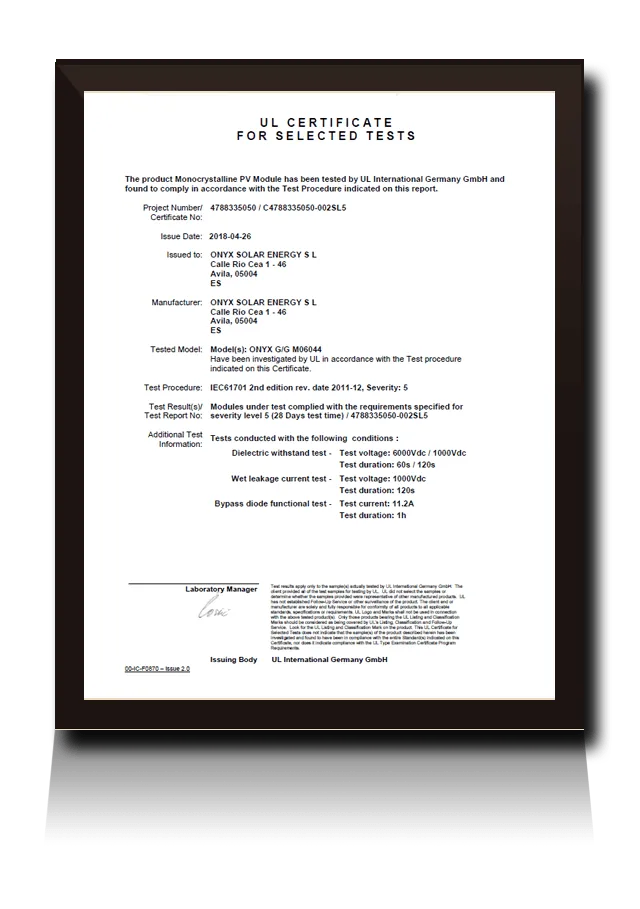

UL laboratories have certified Onyx Solar's amorphous photovoltaic glass panes according to IEC 61646 "Thin-film terrestrial photovoltaic (PV) modules –

Design qualification and type approval". IEC 61646 "Photovoltaic (PV) module safety qualification"

and IEC 61730-1:2004+AMD1:2011+AMD2:2013 standard “Photovoltaic (PV) module safety qualification”.

Part 1: Requirements for construction & Part 2: Requirements for testing

Our PV glass panes are certified in accordance with IEC61701, "2nd ed. 2011-12: Salt mist corrosion testing of photovoltaic (PV) modules" and has reached a maximum of 5 in the scale in the severity test.

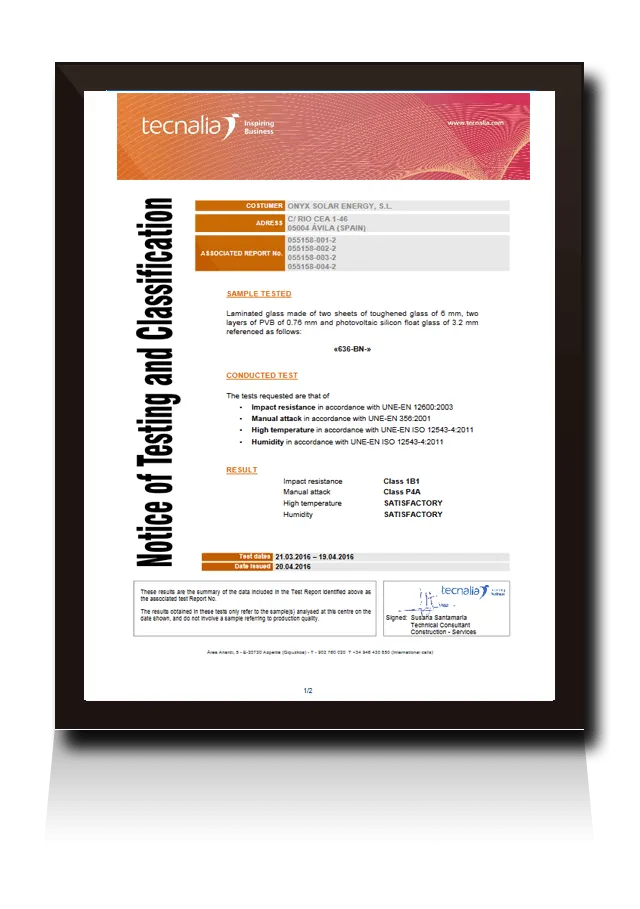

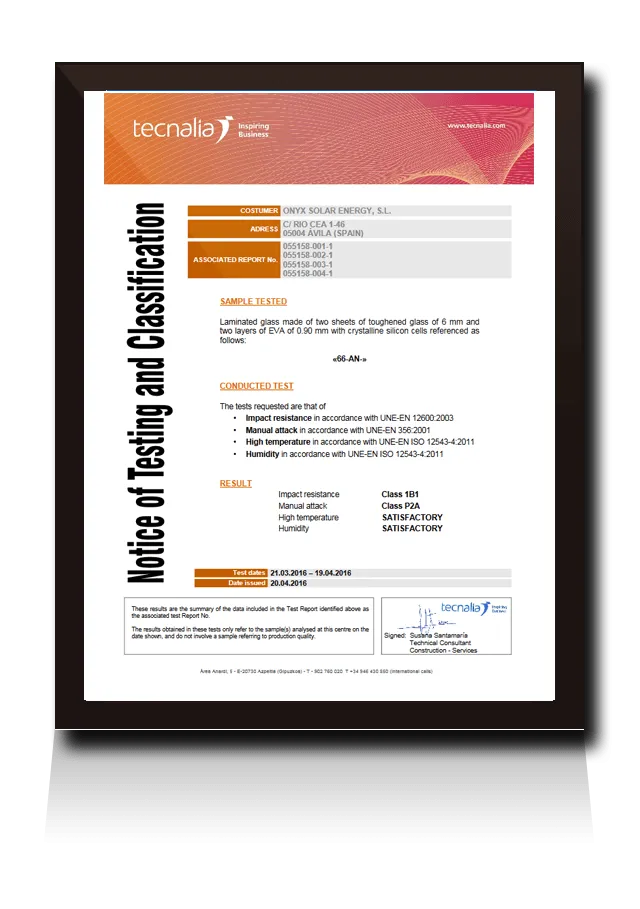

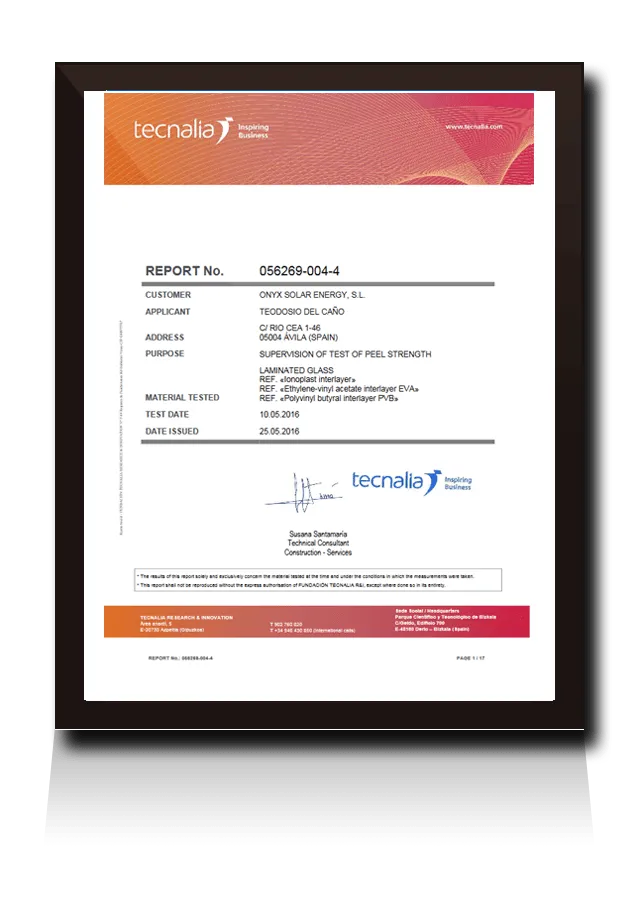

safety standards as architectural glass

In order to prove how the product properly meets the most stringent safety standards in construction required for architectural glass, Tecnalia lab has tested our crystalline and amorphous silicon laminated glass in accordance with the requirements set by the UNE-EN 14449:2006 standard: “Glass in building - Laminated glass and laminated safety glass - Evaluation of conformity/Product” . This is a benchmark standard in the field of architectural glass for building integration. All tests performed have turned out to be a great success.

The glass panes have obtained the best results on the impact resistance tests performed in accordance with UNE-EN 12600:2003 standard.

The amorphous silicon glass panes have got a P4A rating on the resistance to manual attack tests performed in accordance with UNE-EN 356:2001 standard.

Resistance to extreme weather conditions was measured by carrying out a test in accordance with UNE-EN ISO 12543-4:2011 standard. The conclusion reached is that the glass panes can still preserve their lamination quality after having kept them exposed under extreme humid conditions.

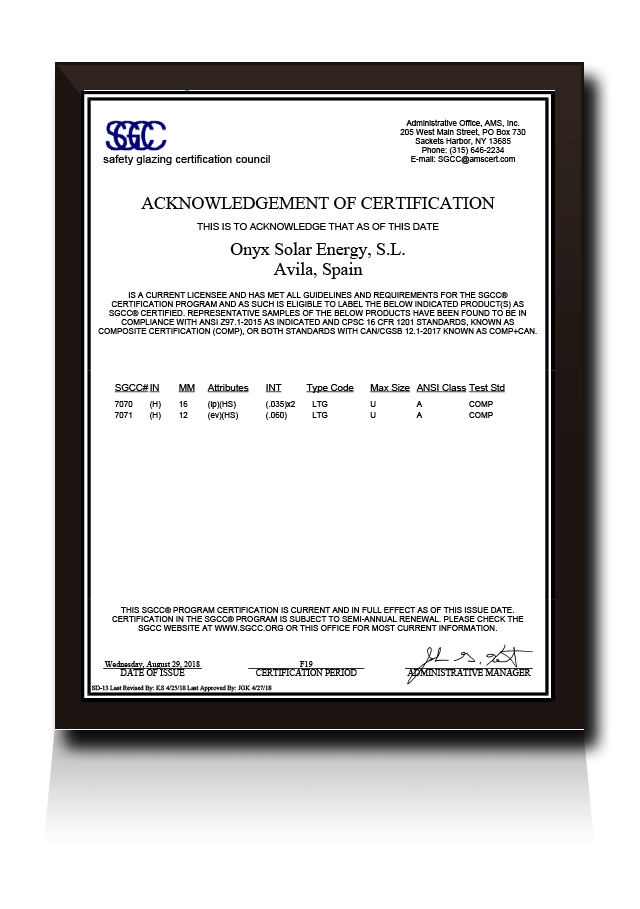

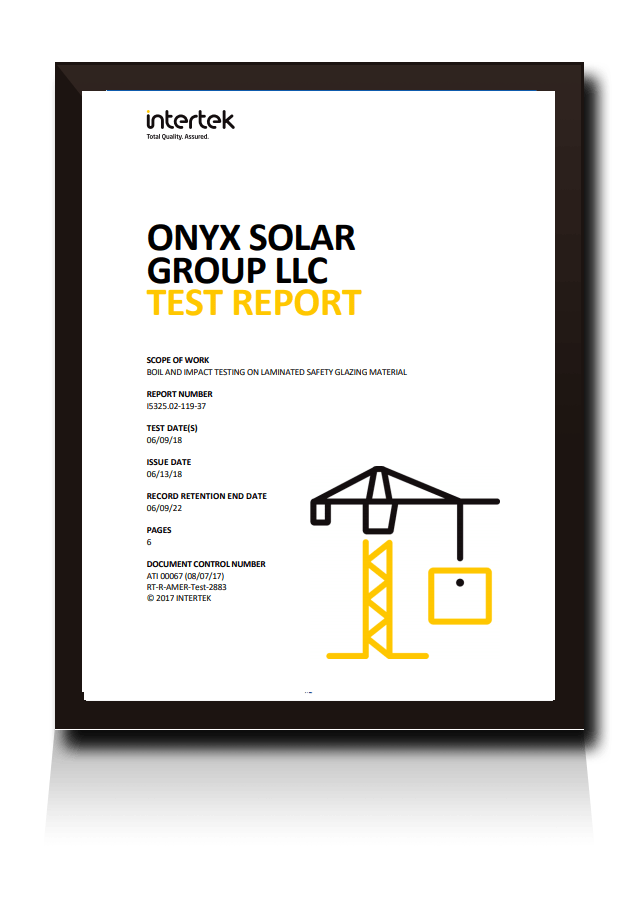

Boil and impact test have been performed in accordance with ANSI Z97.1-2015 standard "For safety glazing materials used in buildings - safety performance specifications and methods of test".

The certifications shown in this section are proof of Onyx Solar’s leadership in photovoltaic glass for buildings.

Integrated Management System

The company has developed an Integrated Management System which has led the company to obtain the corresponding ISO Certifications. Onyx has proved to comply with the requirements of the following two ISO standards: ISO 9001:2005 (Quality Management) and the ISO 14001:2015 (Environmental Management).

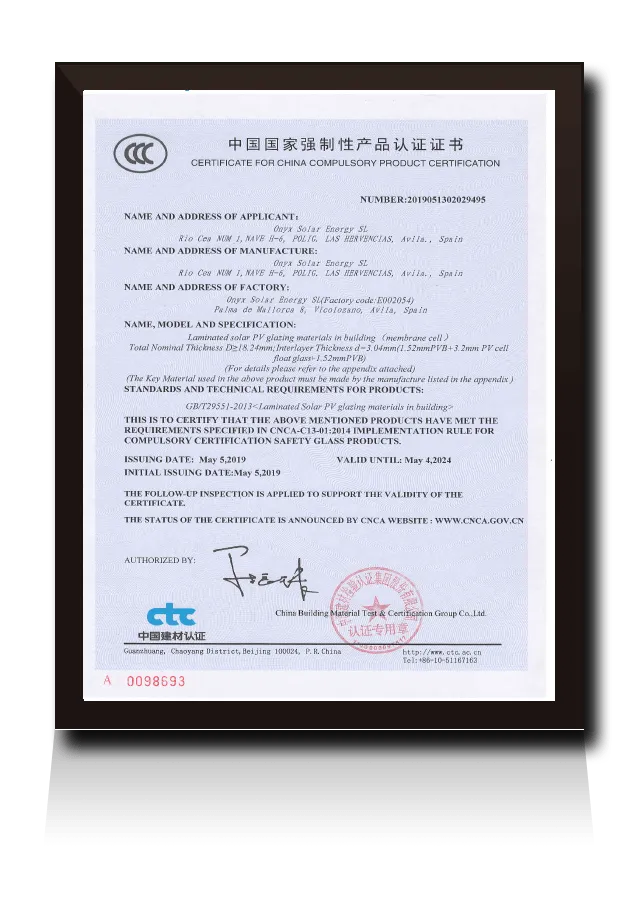

CHINA COMPULSORY PRODUCT CERTIFICATION: Onyx Solar BIPV has met the requirements specified in CNCA-C 3-01:2014 for compulsory certification safety glass products (CCC certification).

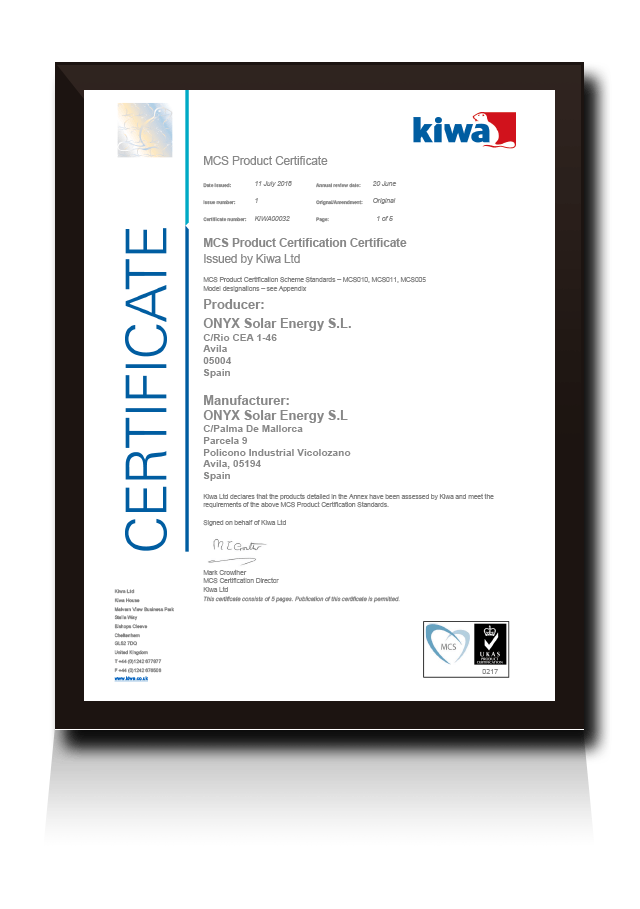

mcs product certification

quality assurance scheme recognised in the United Kingdom, supported by the Department for Business, Energy & Industrial Strategy. It is managed by the MCS Service Company, a trading subsidiary of the MCS Charitable Foundation. MCS certifies microgeneration technologies used to produce electricity and heat from renewable sources. MCS is also an eligibility requirement for the Government’s financial incentives, which include the Feed-in Tariff and the Renewable Heat Incentive.

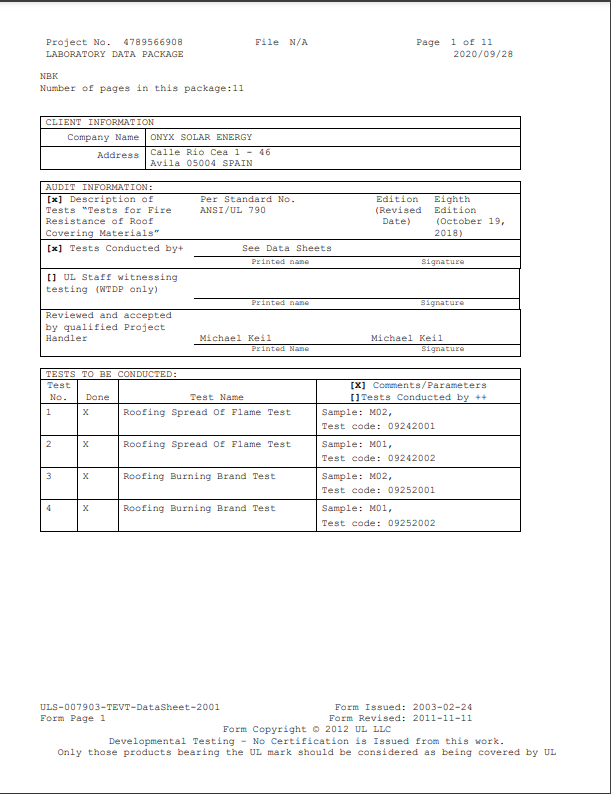

Fire Tests

Our PV glass is classified as CLASS A material as per UL790 and MST 23 & MST24 per IEC 61730-2: 2016

Resistance Tests

Temperature Cycling Test (TC200): Temperature Cycling Test (TC200): 200 cycles of temperature from -40ºC to +85 ºC. |

|||

Humidity Test (HF10): Humidity Test (HF10): 10 cycles of humidity-freezing as 10 cycles of +85 ºC following by freezing stage as 85% relative humidity at -40ªC. |

|||

Damp Heat test (DHT1000): Damp Heat test (DHT1000): 1000 hours at +85 ºC. And 85% relative humidity. |

|||

Mechanical Loading Test: Mechanical Loading Test: Our system can stand up to a tested load of 5400 Pa (540 kg/m2). The deflection of the system (structure and glass) is below L/240 where L is equal to the clear span length in feet of the deflected member. |

|||

|

Light soaking Test: |

|||

Hail test: Hail test: Ice ball in diameter 25 mm at 23 m/s, directed against 11 points of impact. |

|||

Class A on fire safety: Class A on fire safety: Highest rating in fire safety standards. Test standard - ASTM E84-16: Standard Test Method for Surface Burning Characteristics of Building materials. Flame Spread index 25; Smoke-developed index 180. |

For more information, check out our Quality and Environmental Policy.

Amorphous glass

Amorphous glass Crystalline glass

Crystalline glass PV Floor

PV Floor IEC Crystalline

IEC Crystalline Amorphous IEC 61646

Amorphous IEC 61646 Amorphous IEC 61730

Amorphous IEC 61730

Monocrystallime

Monocrystallime Amorphous

Amorphous Crystalline

Crystalline Interlayers

Interlayers 2 ply glass

2 ply glass 3 ply glass

3 ply glass ISO 14001 AENOR

ISO 14001 AENOR ISO 9001 AENOR

ISO 9001 AENOR ISO 9001 IQNET

ISO 9001 IQNET ISO 14001 IQNET

ISO 14001 IQNET